Quality is the cornerstone of every product manufactured by Jiangsu Yawei Transformer Co., Ltd. As a professional manufacturer of power transformers and high-voltage electrical equipment, Yawei integrates rigorous quality control processes at every stage—from initial design to final testing. This end-to-end commitment ensures that all products not only meet but exceed international standards, including IEC, IEEE, ANSI, CSA, and EN, providing customers with reliable, efficient, and safe transformers for a variety of applications worldwide.

The journey of quality begins with design. Using advanced simulation software and engineering expertise, Yawei’s design team develops transformer models that are optimized for performance, durability, and energy efficiency. Whether designing a for a solar farm or a for urban grid infrastructure, every project starts with a thorough analysis of client requirements and environmental conditions. Computational models are used to predict substation transformer thermal behavior, electromagnetic performance, and structural integrity, ensuring that each design is robust and compliant with relevant international standards before moving into production.

Material selection is another critical phase in Yawei’s quality control process. Only high-quality, certified raw materials are used in production. For example, in the manufacturing of , Yawei uses premium-grade epoxy resin and copper conductors to ensure excellent insulation, mechanical strength, and resistance to harsh environments. Suppliers are carefully vetted, and all incoming materials undergo strict inspection to verify their conformity to specifications.

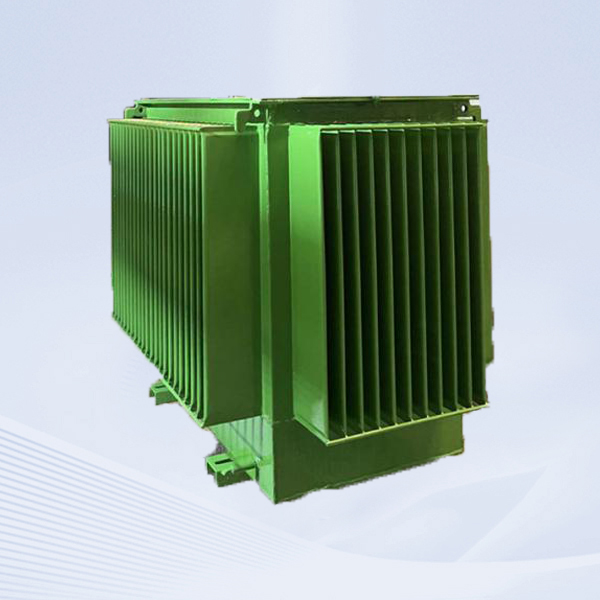

During the manufacturing stage, precision and dry type transformer consistency are maintained through automated processes and skilled craftsmanship. Core assembly, winding, and impregnation are carried out in controlled environments to prevent contamination and ensure dimensional accuracy. For oil-immersed transformers, such as the , vacuum drying and degassing processes are applied to eliminate moisture and gases, enhancing dielectric strength and operational lifespan. Each manufacturing step is documented and monitored, allowing full traceability from raw material to finished product.

Yawei’s dedication to quality is particularly evident in its production of These units are manufactured with low-loss amorphous cores or high-permeability silicon steel, and windings are carefully configured to minimize stray losses. Such attention to detail during production helps achieve higher energy efficiency ratings, reducing electricity waste and supporting global sustainability goals.

Testing is the final and most decisive phase of Yawei’s quality assurance protocol. Every transformer undergoes a series of standard and customer-specific tests to validate its performance and safety. Routine tests includ dry transformere turns ratio measurement, winding resistance test, and insulation resistance check. Special tests such as lightning impulse tests, temperature rise tests, and short-circuit tests are also conducted to simulate real-world operating conditions. For instance, each substation transformer is subjected to impulse voltage tests to ensure it can withstand transient overvoltages, while dry type transformer undergoes thermal cycling and humidity tests to confirm its suitability for indoor and outdoor applications.

Moreover, Yawei’s testing laboratories are equipped with modern facilities such as partial discharge detection systems, frequency response analyzers, and certified calibration instruments. All test results are recorded and compared against international standards before a product is approved for shipment.

This unwavering focus on quality at every stage—design, material selection, manufacturing, and testing—has earned Yawei Transformer a reputation for reliability and excellence across international markets. With products exported to South America, North America, Europe, Asia, Australia, and Africa, Yawei continues to empower industries and communities with transformers that are safe, efficient, and built to last.